Weighing Transmitter high speed 4 channels. Output: RS232/EthernetIP

Available in several variants

| DGT4X | € 699,00 | |

| DGT4XAN | € 755,00 | |

| DGT4XPB | € 909,00 | |

| DGT4XPRONET | € 909,00 | |

| DGT4XETHCAT | € 955,00 |

Description

4-channel weight transmitter for weight transfer to PLC via fieldbus, analog output or RS485.

It allows the reading and diagnostics of each load cell or each connected scale.

Available versions:

PROFINET I/O | ETHERNET/IP | ETHERCAT | MODBUS TCP | CANOPEN | DEVICENET | PROFIBUS | ANALOG OUTPUT | RS485

Integrated WebServer as standard for configuration, diagnostics and data backup.

What's new compared to DGT4

- New cutting-edge processor, able to process up to 2600 weight readings per second. The high speed allows an extremely accurate weight filtering even with weighing times in the order of milliseconds.

- New cell feed circuit for greater weighing stability.

- Power supply circuit with protections, specific for industrial environments.

- Removable terminal blocks to simplify wiring in the electrical panel.

- Frontal micro-USB communication port for configuration, diagnostics and data backup.

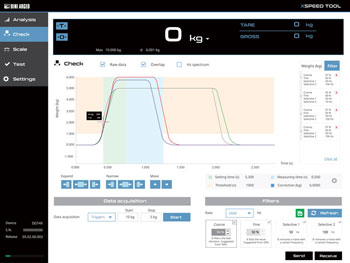

- XSPEED TOOL: New PC software with oscilloscope function for system diagnostics and weighing filter optimization.

- 14.2 mm display.

- New configuration menu to simplify calibration and configuration.

- RS485 communication port always available on all versions.

- Up to 120 fieldbus updates per second.

ONBOARD WEB SERVER

The integrated WEB SERVER allows complete diagnostics, calibration and remote configuration of the weight transmitter from the Ethernet network. Only for PROFINET, ETHERNET/IP and MODBUS TCP/IP models.

PC XSPEED TOOL SOFTWARE

- Specific program for PC, designed to improve the performance of any weighing system.

- Customization of the weighing filter, to maximize the speed and accuracy of the weighs in static and dynamic applications.

- Graphical weighing analysis for the identification of mechanical disturbances and vibrations.

TECHNICAL FEATURES

- Power supply: 12-24Vdc

- Converter: A/D 24 bit with 4 channel

- Max scale number: 4

- Load cells connection: 4 or 6 wires (with sense)

- Operating modes:

- Digital junction box

- Multi-scale transmitter

- Single-scale transmitter - Conversion rate: up to 3200 conv./sec

- Selectable sampling rate: up to 2600 conv./sec

- Fieldbus update rate: up to 120 Hz

- Displaying: up to 1.000.000d

- Signal sensitivity: 0,03 µV/d (0,3 µV/e)

- Resolution: 3.000.000 counts

- Linearization: up to 8 points

- Connectable load cells: up to 16 350 Ω cells

- Fieldbus: Profibus, Profinet, EthernetIP, EtherCAT, EthernetIP, CANopen, DeviceNet, Modbus TCP/IP.

- Serial ports:

- 1 Micro-USB port (device) for PC configuration with "Dinitools®" and "XSpeed Tool".

- 1 RS485 port

- 1 RS232 port (Mod. DGT4X / DGT4XAN) - Analog output: 16 bit (DGT4XAN Model) 4-20mA or 0-10Vdc.

- Digital outputs: n. 2 configurable OUTPUTS

- Digital inputs: n. 2 configurable INPUTS

- Certifications:

- OIML R76 (10000e or 3000 + 3000e) / R51 / R61 MID

- UL Listed (upon request)

- EU Type Examination Certificate (45501:2015) - Case: ABS, for Din bar (106 x 56 x 118 mm)

- Calibration:

- Theoretical (mV\V)

- With sample weights

- Remotely by WEB SERVER

- From the keyboard

- From PC with "Dinitools" - Keyboard functions:

- Zeroing, Tare, Function mode, Manual data printing/sending, ON/Stand-by - Program functions:

- Setpoint, High resolution, Peak, Alibi Memory, Unit of measure conversion - Keyboard: mechanical with 5 digits

- ?Display: 14,2mm red LED

UPON REQUEST

- UL certified version

Accessories / Spare parts

Showing 10 / 10

Is accesory to

Showing 2 / 2

Others also bought

Related pages

DIN performance indicators

All load cells are connected to some sort of electronics. The simplest is a transmitter which only gives a signal to a computer or PLC. The next step is indicators with zeroing (null-positioning) and tare and other functions.

Transmitters

All load cells are connected to some sort of electronics. The simplest is a transmitter which only gives a signal to a computer or PLC. The next step is indicators with zeroing (null-positioning) and tare and other functions.

Weighing indicators

All load cells are connected to some sort of electronics. The simplest is a transmitter which only gives a signal to a computer or PLC. The next step is indicators with zeroing (null-positioning) and tare and other functions.